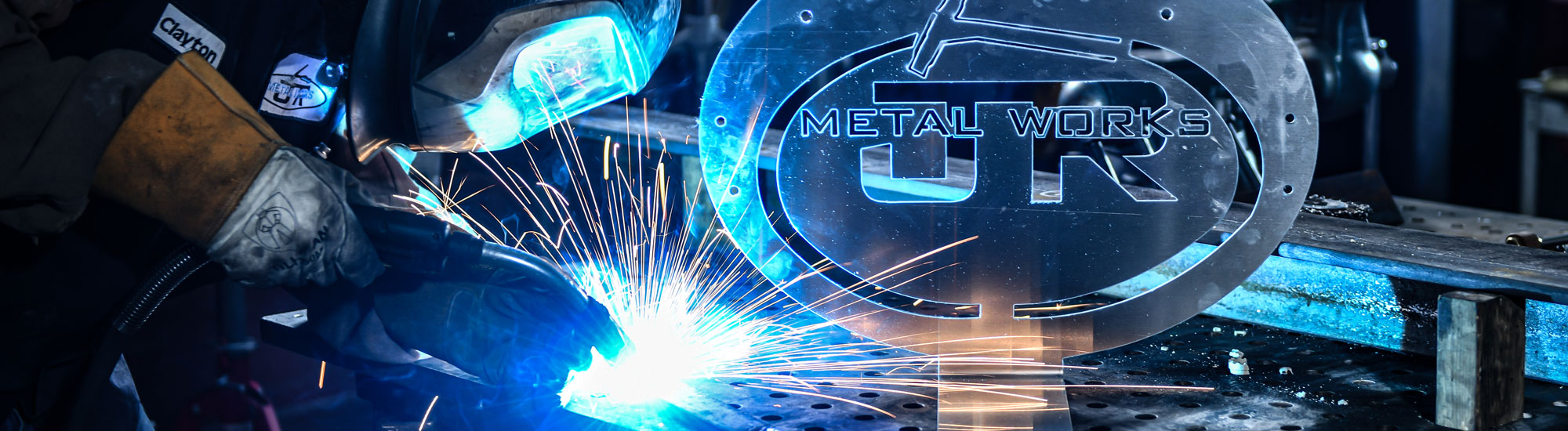

WELDING

A core part of JR Metal Works’ full-service metal fabrication capabilities is our welding services, which create the durable bonds that hold assemblies together. It takes skill and experience to achieve seamless fusion with the strength to meet demanding industrial, commercial, and military standards.

JR Metal Works holds those standards in high regard, treating welding as an artisan craft that requires an expert D1.1- and API 1104-certified team. JR Metal Works’ welders’ extensive knowledge and attention to detail embody the company’s commitment to customer satisfaction. They deliver welds ensuring your parts are structurally sound. The JR Metal Works welding team provides custom welding services, creating solutions for industries such as aerospace, defense, medical, and utilities.

Welding Processes

- GMAW (Gas Metal Arc Welding)

- GTAW (Gas Tungsten Arc Welding)

- FCAW (Flux Core Arc Welding)

- SMAW (Shielded Metal Arc Welding)

Welding Codes

- D1.1 Structural Welding Code-Steel Plate

- API 1104 Welding Code-Steel Pipe

Material Capabilities

- Steel and Steel Alloys

- Aluminum welding services

- Stainless Steel

- Sheet, Pipe, Plate, and Structural Shapes to Unlimited Thickness

- Titanium

- Other materials available upon request

Welder Testing/Training

- Welder continuity tests every 6 months

- Welder continuity logs

- Local partners for a variety of destructive and non-destructive testing

In addition to welding, JR Metal Works offers turnkey metal fabrication services, including 3D digital modeling, CNC waterjet cutting, CNC forming, hardware insertion, finishing operations, and assembly.

By combining welding with other specialized welding services and fabrication processes, customers benefit from quality, efficiency, and precision at every stage.